The Climate Board - the Original by CALSITHERM

CALSITHERM Climate Boars are made of natural raw materials - sand and lime (calcium oxide and silicon dioxide). In an autoclave process, under superheated steam and high pressure, the mineral raw material converts into tiny calcium silicate crystals. The crystals are bound to each other by billions of micro-pores and thus enable the high water absorption and the enormous transport capacity. Thus, the climate boards have a tremendous moisture regulating effect and prevent the formation of condensate. This contributes to long-lasting mould prevention - even in problem areas.

The non-flammable insulation material is approved by the building authorities and classified by the Institut Bauen und Umwelt e.V. (Building and Environment Institute) as an environmentally-friendly construction product.

We distribute exclusively through the specialist traders of building materials and wholesalers supplying to painting businesses, when it comes to energy-efficient renovation of private or commercial buildings. Our partners are architects and civil engineers, together with whom we develop solutions.

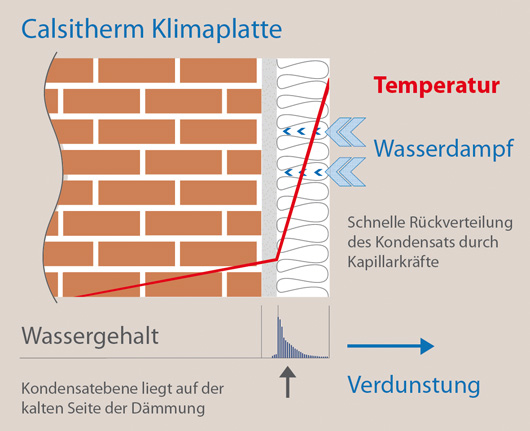

Working principle

The temperature difference between indoor and outdoor climate causes ingress of water vapour into the structure. This phenomenon is reinforced by an internal insulation. Particularly in the case of diffusion open systems, there is a measurable moisture development on the cold side of the insulation material.

This condensate is absorbed by the capillary-active Climate Board, transported to the inner surface and from there it is released into the air in the room. The short-term absorption of the temporarily high humidity (for instance, after showering) creates the comfort that the CALSITHERM climate board is famous for.

Base:

Suitable bases are, for instance, stable and flat lime or lime-cement plasters. Wallpaper, paint, gypsum coatings and loose constituents should be removed. Construction defects and penetrating moisture should be eliminated through suitable measures. Absorbent surfaces must be pre-wetted or primed. A decoupling from the adjacent structural elements such as floors, ceilings and windows must be provided for. Unevenness on the surface must be levelled out before applying the boards.

Machining:

The Climate Board can be cut to the desired size using a rip saw, a pendulum action jigsaw or a circular saw. Boards of up to 30 mm thickness can also be cut by scoring with a sharp blade and then folding up. The cut edges should be smoothed using a rasp. When cutting the boards indoors, appropriate dust protection measures should be taken.

Processing:

For gluing the Climate Board, the KP Adhesive is mixed according to the instructions, applied to the wall covering the full surface and combed through horizontally using the KP notched trowel (10 mm toothing) to spread evenly. In case of larger unevenness, the wall should be plastered beforehand with KP levelling plaster.

Starting from the bottom, the boards are glued with the textured side to the wall. Before that, an appropriate decoupling from the floor needs to be ensured so as to avoid a back flow. Once the board is positioned, it is pressed firmly. The next board is butted to the previous one. Alternatively, in case of homogeneous climate boards, adhesive should be applied to the butting edges before fitting the next board. The joint width must not exceed 3 mm. The excess glue is picked up cleanly.

Surface:

It is important to have a careful vertical and horizontal execution of the bottom row of boards so that the boards can be butted neatly. Moreover, cross joints should be avoided. CALSITHERM Climate Boards are already primed on the smoothed side at the factory. However, the surface coating should only be applied after the adhesive has set.

Depending on the desired texture, the surface can be coated with a rough (slightly grainy) plaster KP Innenputz, or a smooth plaster KP-Kalkglätte. For a crack-free surface, the application of the reinforcement mesh KP-Gewebe is recommended. In the ceiling area, the climate boards are additionally fastened with insulation anchors so that a secure position is ensured for a long time. Furthermore, the decoupling from swinging structural elements such as window frames or floating floor screeds should be considered.

Technical Data - Climate Board:

| European Technical Assessment | ETA-15/0340 |

| Dry bulk density | 180 - 187 kg/m³ |

| Thermal conductivity, measured value | 0,062 W/(m∙K) |

| Thermal conductivity, nominal value λD | 0,059 W/(m∙K) |

| Water vapour diffusion resistance factor | μ = 3 |

| Cold crushing strength | > 1 MPa |

| Building material class according to DIN EN 13501 | A1 non-flammable |

| Environmental Product Declaration | EPD-CSP-20180010-IBC1-DE |

Climate Board Dimensions:

| Length | 1.255 (625) mm |

| Width | 1.000 (500) mm |

| Thickness | 25, 30, 50, 80 mm |

| available in other thickness | 20 - 120 mm |

Get in Contact

CALSITHERM Silikatbaustoffe GmbH

Hermann-Löns-Straße 170

33104 Paderborn

Tel.: +49 (5254) 990 92-0

Fax: +49 (5254) 990 92-17

E-Mail: info@calsitherm.de